-

Name

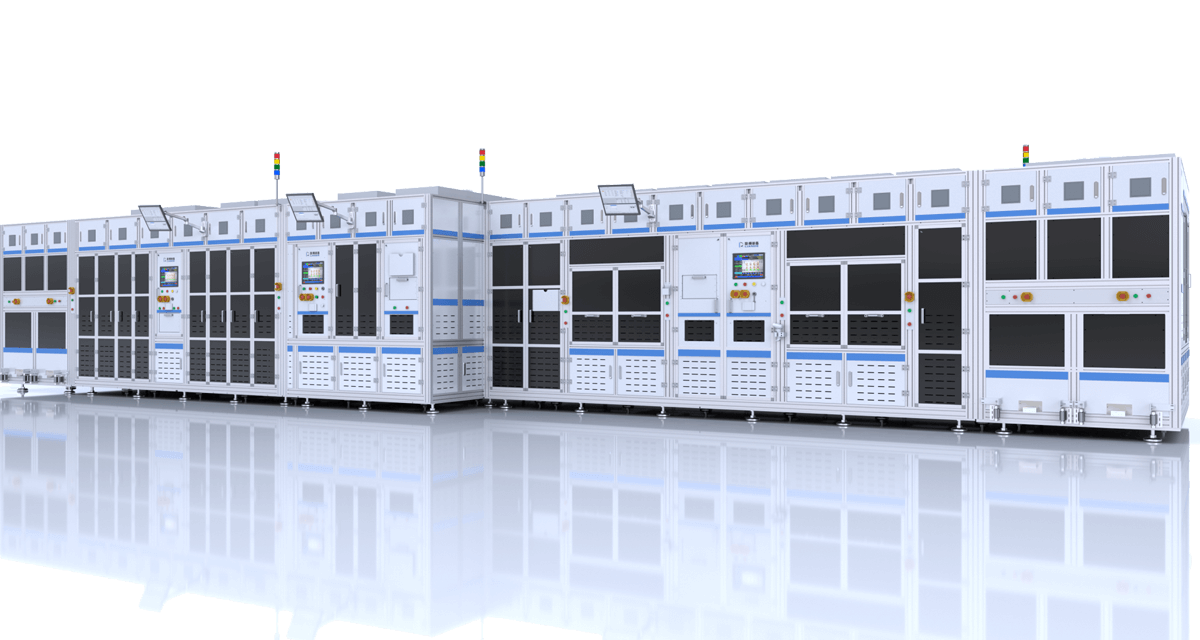

Fully automated Copper Foil Film Attachment & Lamination Equipment Line

-

Function

Applying protective film to the CG surface and laminating copper foil onto panels

-

Product Size

5-10Inch, Maximum size-220×260mm, Minimum size-80×50mm

-

Efficiency

3.5s

-

Equipment Accuracy

±0.15mm

-

Equipment dimensions

L16000×W3400×H2200mm (For reference only)

-

Technical Avantages

Supports multiple loading methods: Z-fold materials, reel-fed, sheet-fed;

Enables top-side and bottom-side lamination methods;

Capable of laminating copper foil, SUS steel, and panels;

Developed protective film attachment & thermal dissipation film lamination technology;

Bi-curved and quad-curved surface lamination capability;

Equipment yield 99.99%, low alarm rate, uptime over 95%.

-

Technological Process

Panel loading → Cleaning-Protective film Attachment-Inkjet marking - Film Peeling → Cleaning → Copper foil laminating → AOI Inspection → Finshed product unloading

Fully automated Copper Foil Film Attachment & Lamination Equipment Line

Fully automated Copper Foil Film Attachment & Lamination Equipment Line executes: protective film attachment and thermal dissipation film lamination through process flow: material loading → cleaning → film attachment → inkjet marking → film peeling → cleaning → copper foil laminating → AOI inspection → auto-unloading.

Technical Specification

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you