-

Name

COF Flip Chip Eutectic Bonder

-

Chip Size

W: 1.5-5mm, L: 15-25mm, T: 0.2-1mm

-

TT

1.5sec(UPH: ~2K)

-

Accuracy

±1.5μm

-

Die Bonding Capacity

10-350N

-

Temperature

Chip side: 200-450℃

Substrate: 100-150℃

-

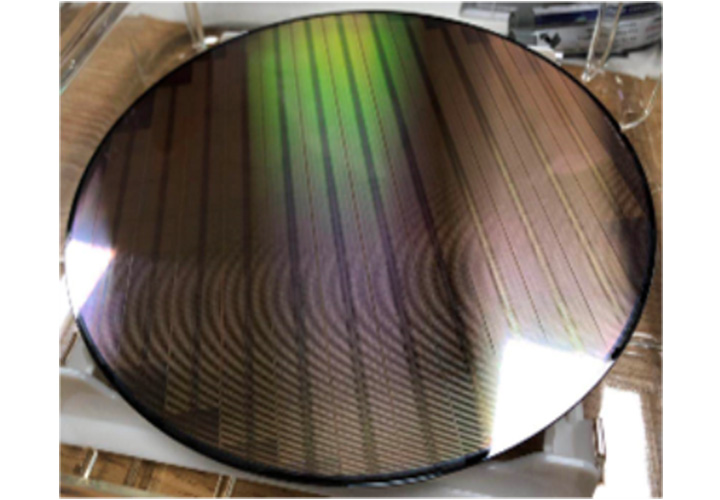

Wafer Size

8 inch and 12 inch

-

Substrate Size

35/48/70mm;25-112μm in thickness

-

Die Bonding Process

Flip chip & Eutectic bonding

-

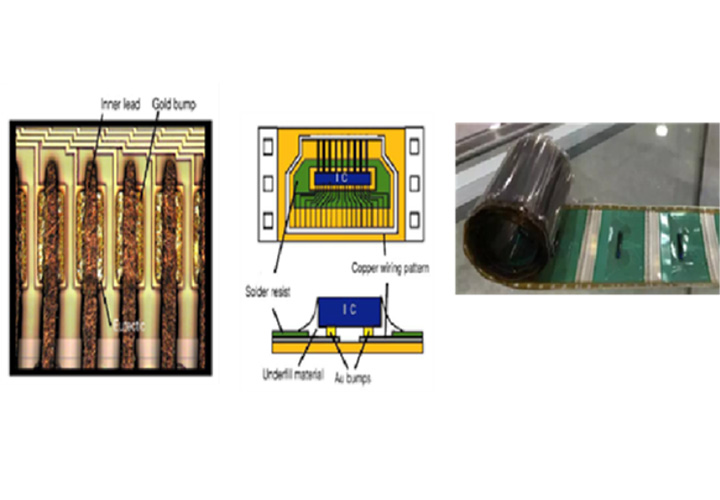

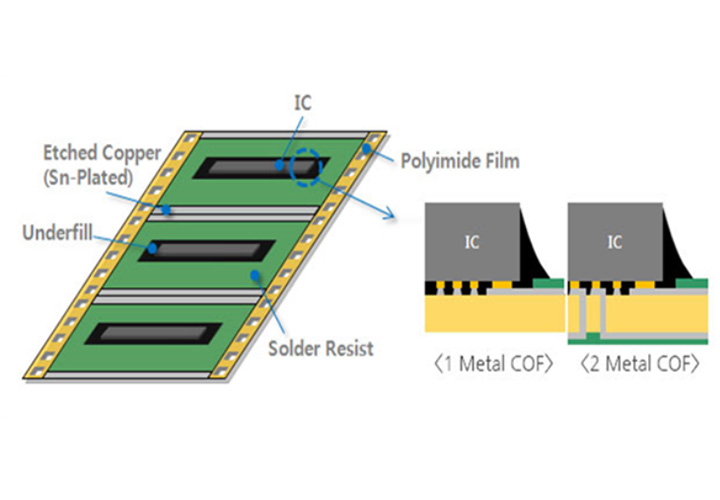

COF Technology & Applications

COF (Chip on Film) is an IC packaging technology that bonds the Gold Bump on chips to the Inner Lead on flexible circuits via thermal compression.

COF is one of core components for LCD/OLED displays, COF Bonding adopts flip chip eutectic method.

COF Flip Chip Eutectic Bonder

The high-precision flip-chip eutectic bonding process interconnects display driver chip bumps with substrate leads to enhance packaging density and performance. This critical packaging equipment is widely applied in LCD/OLED display driver applications.

Details

Technical Specification

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you