-

Name

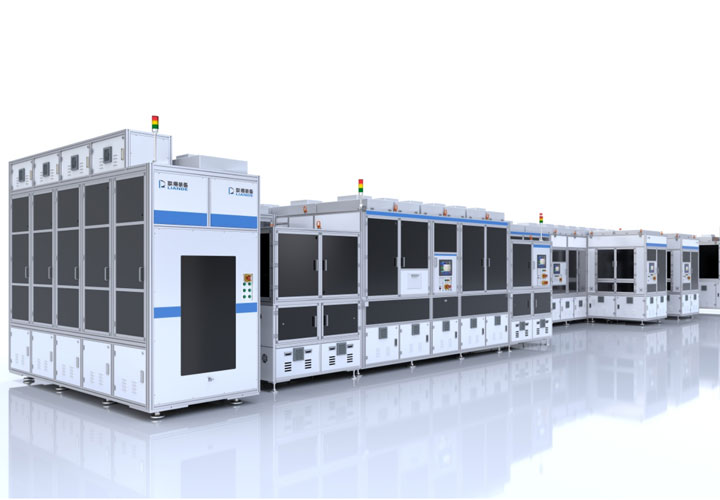

Fully automated Flexible Screen FOP Bonding & Inspection Full Line

-

Product Size

10-23Inch

-

Takt Time

10s (Single-side mounted quad FPC connectors)

15s (Single-side mounted hex FPC connectors)

-

Equipment Accuracy

ACF Bonding Accuracy: ±0.15mm(3σ),Y:±0.1mm(3σ)

FOP:XY:±10μm(3σ)

FOB:X:±25μm(3σ),Y:±35μm(3σ)

-

Equipment dimensions

L20450×W3550×H2200mm (For reference only)

-

Technical Avantages

Fully automated in-line loading/unloading;

Automated stringing operation;

Customized vacuum gripping suction for 10-23-inch flexible screens (anti-deformation design);

Class 100 cleanroom compliance throughout equipment

-

Technological Process

LD → EC → FPC Bonding → AOI+ART Inspection → FOB Bonding → FOB ART Inspection → ULD

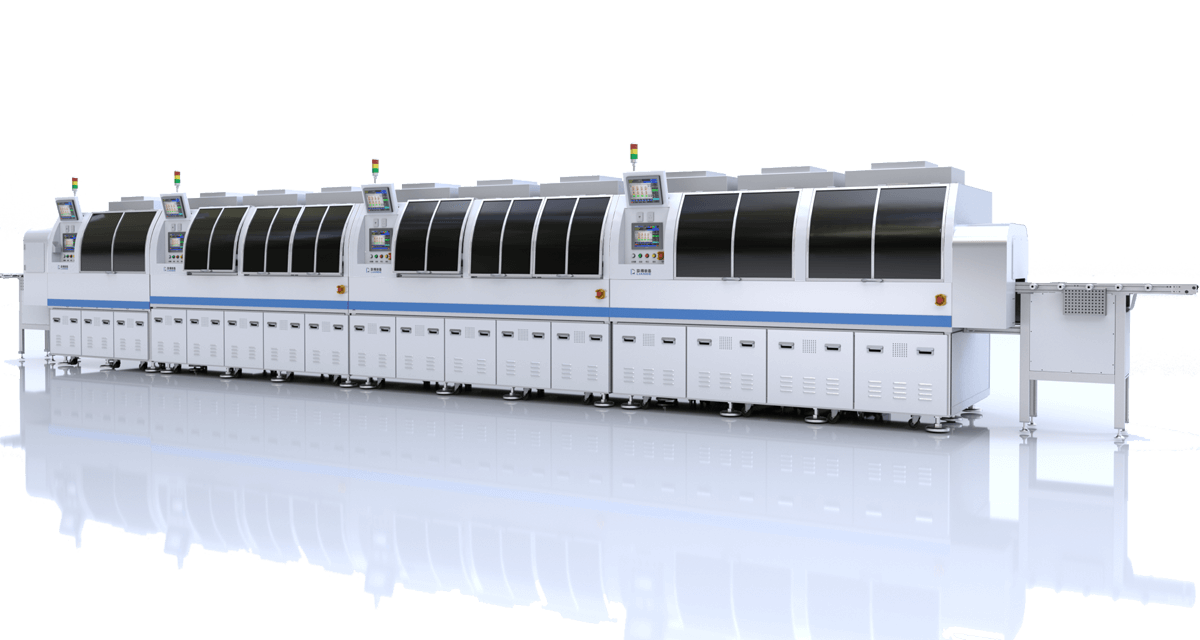

Fully automated Flexible Display FOP Bonding & Inspection Full Line

Fully automated Flexible Display FOP Bonding & Inspection Full Line, applied for flexible screen under 23'', featuring:

- Auto-loading,

- Top&bottom USC cleaning

- Terminal Plasma cleaning

- FPC auto-loading → Cleaning → Auto-bonding

- Post-bonding AOI offset & ART impedance inspection

- PCB auto-loading → Cleaning → Auto-bonding

- Unloading machine (compatible with dual-layer AGV material carts)

Technical Specification

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you