-

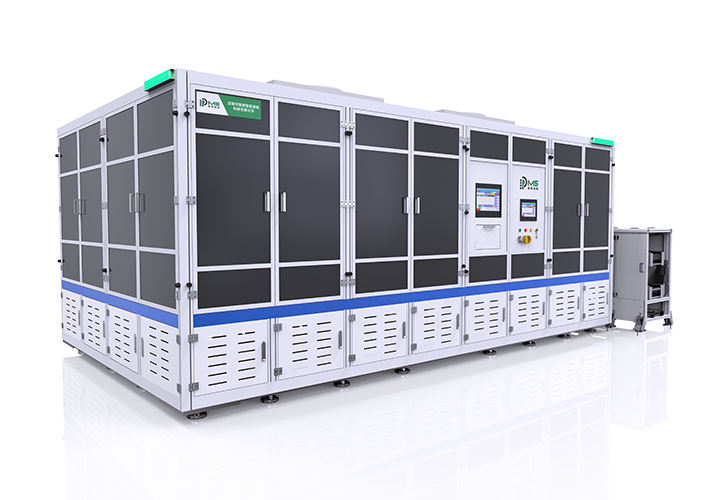

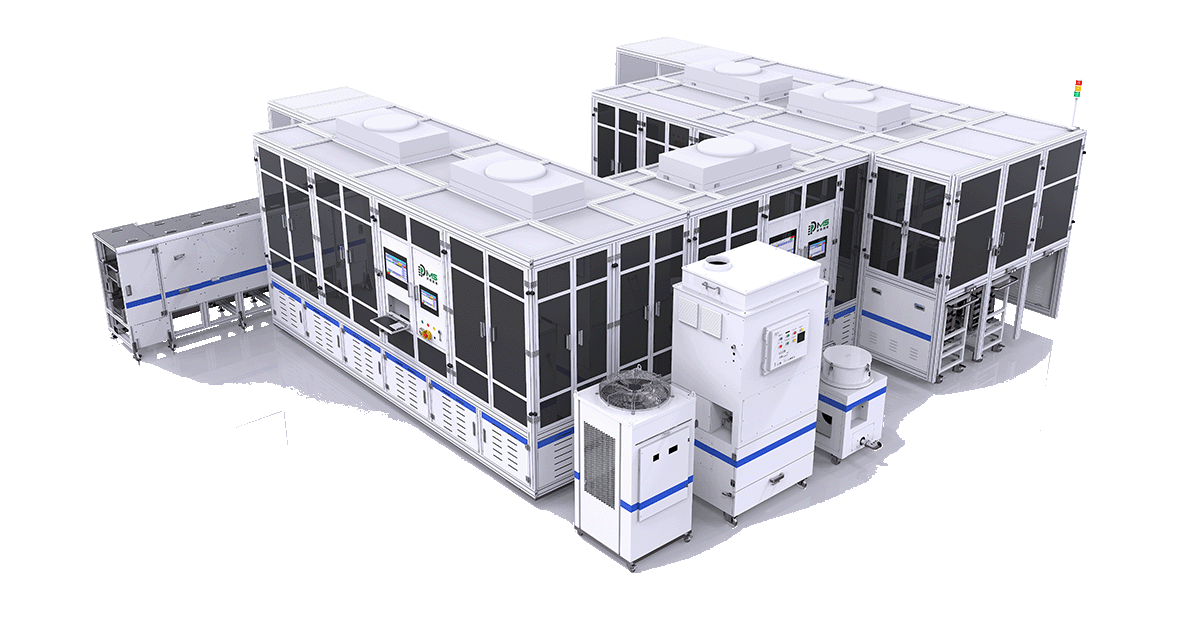

Name

Interconnect Tab Laser Welding Machine

-

Unit Capacity

Max15PPM

-

Applicative Cell Dimensions

140-180mm(W)

85-220mm(H)

20-80mm(T)

-

Welding Alignment Accuracy

≤±0.3mm

-

Post-assembly Misalignment

≤±0.5mm

-

Laser Welding Speed

≤±130mm/s

Interconnect Tab Laser Welding Machine

The interconnect tab laser welding machine, functioning as the assembly-stage welding equipment for prismatic lithium batteries, features various functions, such as tab-to-cover welding, weld seam taping, cell stacking, and insulation wrapping. etc.

Details

Technical Specification

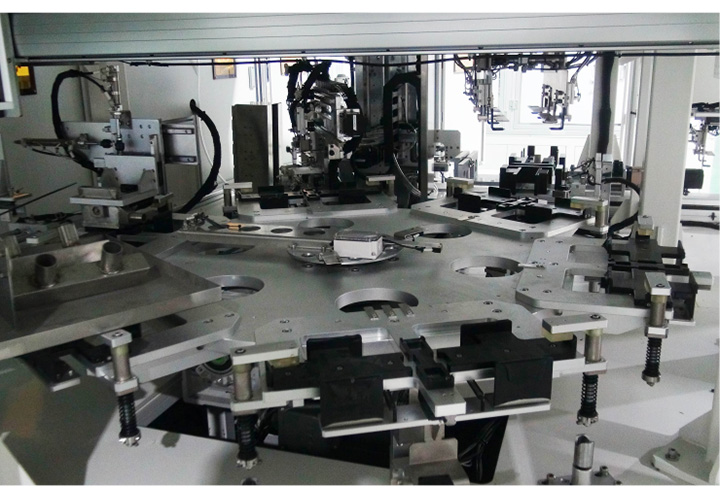

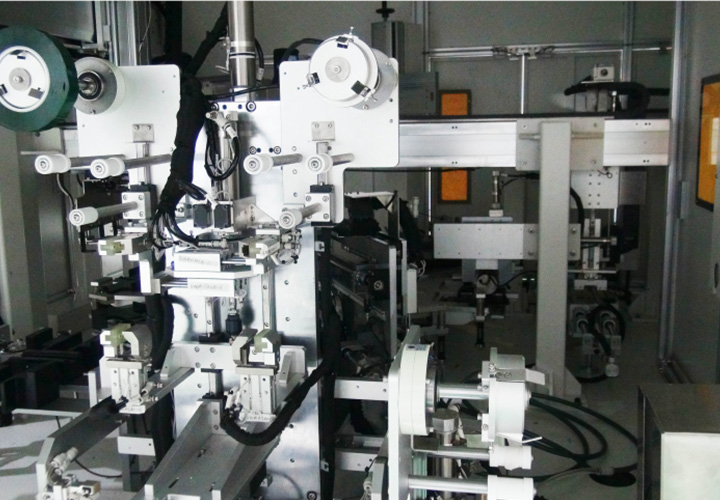

Equipment characteristic

- Coaxial dust extraction in laser welding zone

- DD motor-driven indexing marking turntable, easy debugging and with high flexibility

- Multi-protection welding process

- 8-station turntable with compact layout & non-stop material loading

- Integrated welding turntable, delivering handling cycles reduction, minimized displacement and lower defect rate

- Broad product compatibility with rapid changeover

Optional configurations

- U-type adhesive applicator with weld seam CCD real-time monitoring

- Side wrapping for post-assembly of cell, cover loading via roller conveyor

- Weld cleaning module, material handling by 6-axis robot

- Code scanner and floating gripper

- Image-based secondary alignment, AGV-based cover loading

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you