-

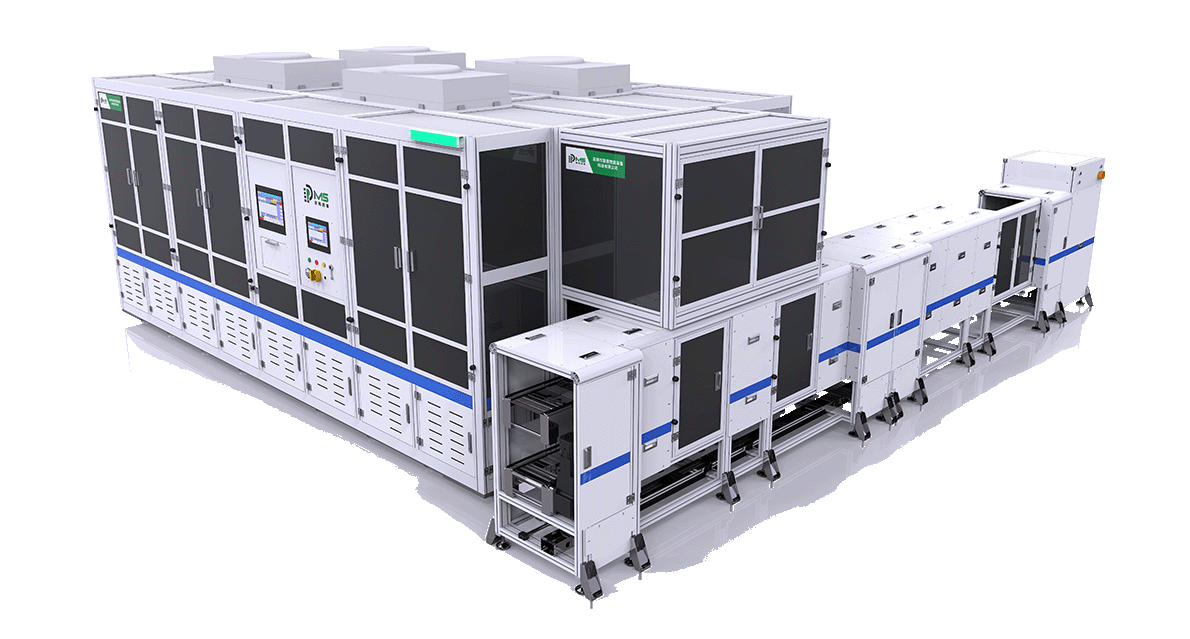

Name

Polyester Film Wrapping Machine

-

Unit Capacity

≥8PPM

-

Applicative Cell Dimensions

140-180mm(W)

90-220mm(H)

20-80mm(T)

-

Heat Sealing Temperature

150-220°C, accuracy±0.3°C

-

Heat Sealing Time

1-5s (0.1s adjustment precision)

-

Film Edge Positioning Accuracy

±0.1mm

Polyester Film Wrapping Machine

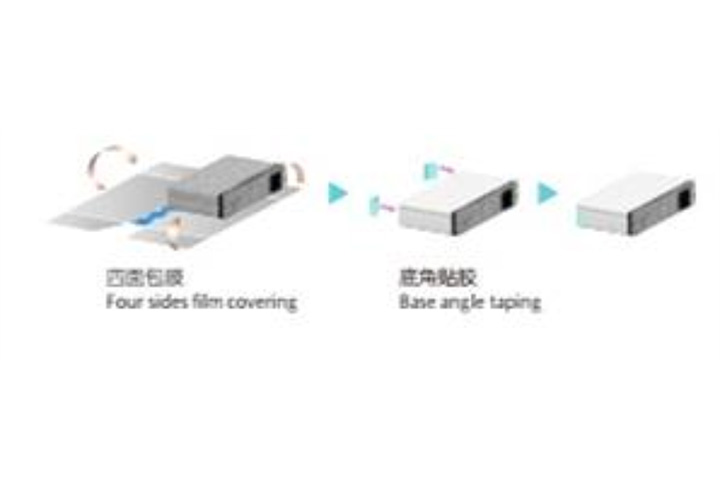

The Polyester Film Wrapping Machine performs heat sealing of Mylar film to the baseplate insulating sheet, Mylar film full-wrap encapsulation, and Mylar-to-top bracket for prismatic lithium battery cells during assembly.

Details

Technical Specification

Equipment Features

- Multi-axis rotary wrapping film mechanism with high edge alignment accuracy

- Film-to-cover-referenced edge alignment accuracy: ±0.5mm

- Close adhesive attachment of film and cell, rare to produce edge lifting and air pockets

- Non-stop Mylar and carrier plate loading with 2-hour replenishment cycle

- Compact layout with multi-station turntable or linear conveyor system, delivering multi-capacity compatibility

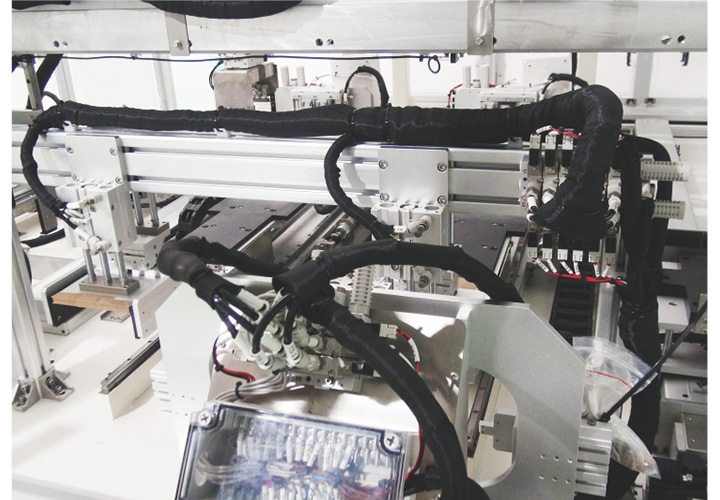

- 4-axis robot for cell/insulator integrated handling, reducing gripping cylces and with a minimized displacement

- Broad product compatibility with rapid changeover capability

- Weld coverage ratio >50%, tensile strength >10N per weld

Optional configurations

- 4-axis robot for insulator loading

- Film lamination module: film flipping position detection/rotary wrapping

- Material handling execution: 6-axis robot with full model compatibility

- Bottom tape position CCD inspection

- Material handling(loading/unloading) floating gripper

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you