-

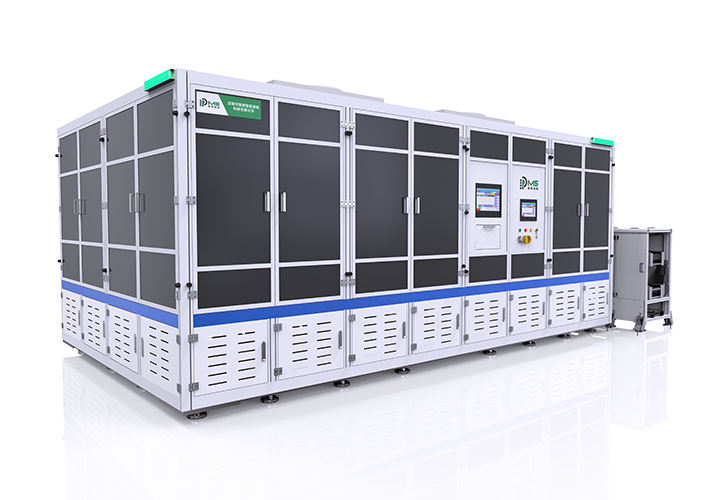

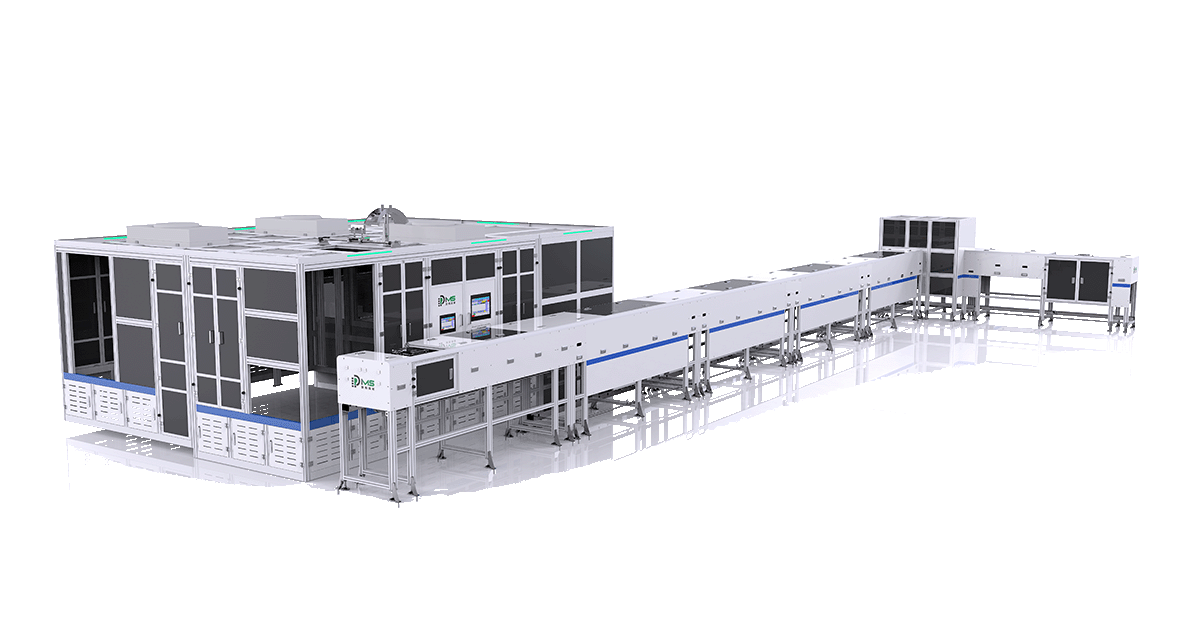

Name

Core-to-Casing Prewelding Machine

-

Unit Capacity

15PPM

-

Applicative Cell Dimensions

140-180mm(W)

90-220mm(H)

20-80mm(T)

-

Cover-shell Step Height

≤0.25mm

-

Cover-shell Clearance

≤0.08mm (1/10th shell thickness)

-

Welding Positioning Accuracy

±0.1mm

Core-to-Casing Prewelding Machine

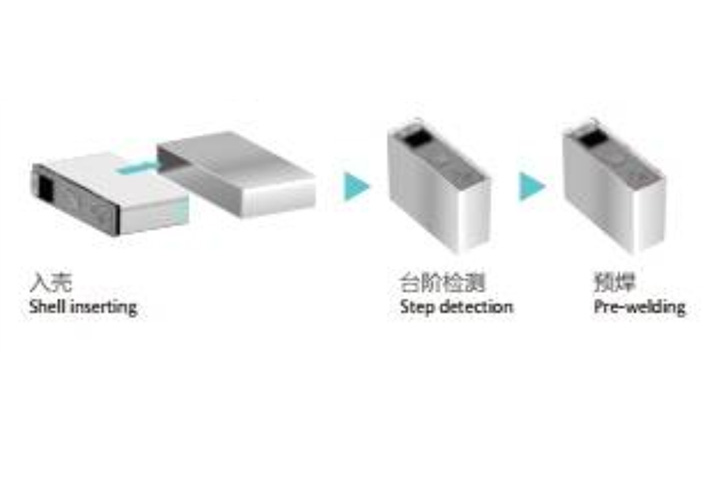

The core-to-casing prewelding machine executes bare core insertion and compression flattening in aluminum casings for prismatic lithium batteries, while prejoining cell covers to casing openings.

Details

Technical Specification

Equipment characteristic

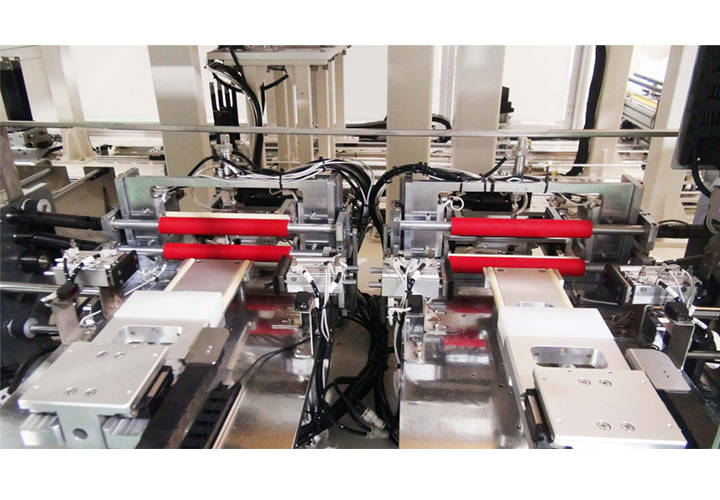

- Real-time pressure monitoring during cell insertion

- Automatic cell-can centering correction

- Full-shielding at shell opening with JR-protected configuration

- Inspection function between cover face & shell opening

- Two-stage insertion with post-insertion Hi-Pot testing for stage one

- 4-axis robot for cell/insulator integrated handling, reducing gripping cylces and with a minimized displacement

Optional configurations

- Cell top cover ultrasonic cleaning

- Shell AGV-based automatic loading

- Shell Code scanning function, Code scanner

Related Products

Are you looking for the right solution for your industry?

If you are looking for best solution to improve your productivity, please contact us, and we will be happy to assist you